Recent market trends have benefited UK clothing manufacturers as many large retailers have 'reshored' all or part of their product sourcing. Our guide covers the key issues for starting and running your own clothes manufacturing business.

- Research the clothing manufacturing industry

- Establish your customer profile

- What clothing will you produce?

- Production methods

- Fairtrade clothing production

- Promoting your manufacturing business

- Pricing policy

- Buy an existing clothing manufacturing business

Research the clothing manufacturing industry

Estimating demand

It's very important to confirm that there's enough demand for the clothing ranges you propose to produce.

The UK clothing industry is highly competitive, with consumers forcing down retail prices, which in turn puts pressure on the prices that clothing manufacturers can charge. There are very many small firms which are prepared to work on low profit margins.

In the past many manufacturers worked mainly for the High Street clothing retailers, supplying goods under the retailer's own labels. However these customers are increasingly sourcing their garments from overseas, where labour is cheaper, so that they can still offer competitive prices to consumers while protecting their own profit margins.

This makes it very difficult for a new clothing manufacturer to compete at the mass-produced end of the market.

There are opportunities, however, for manufacturers offering ranges for a 'niche' market. For example this might be:

- producing a particular, specialised type of clothing such as work wear, performance sportswear or cold weather garments

- using innovative designs and fabrics to produce exclusive, up-market clothing ranges

- focussing on using very high quality yarns and fabrics to produce limited numbers of garments

- supplying garments for the more exclusive clothing labels

- producing ranges for outlets such as 'country pursuits' retailers, tourist visitor centres, airport shops and so on

You should keep an eye on what is fashionable at the moment and consider satisfying that market. For example, athleisure wear, which is clothing designed for sport or as gym wear that is worn more generally as casual clothing and for social occasions, has been very popular.

Have a good look at your target retailer customers to see if they already sell similar clothing ranges to the ones you propose to produce. Why will yours be more successful? Identify the things that make your garments more attractive to customers.

Whatever the clothing range you have in mind, it would be helpful if you could produce some samples. You could then approach individuals (such as retailers and buyers) and organisations (such as wholesalers) which might be interested in selling your products. Discuss with them the price of the products and draw their attention to any special features such as:

- textiles manufactured in the UK (for example Irish linen, Yorkshire woollen fabrics, East Midlands knitted fabrics)

- use of innovative new textiles - for example designed to repel stains

- garments hand-finished

- limited production runs

- carved bone buttons

- rapid delivery times

- plus sizes available

When you are showing your samples to prospective customers, you could take the opportunity to discuss:

- the minimum value or volume that applies to orders

- how much business they might be prepared to put your way

You could also ask them:

- their opinion of your clothing ranges

- what they think of your pricing and terms

- whether they have any suggestions for improvements or enhancements to your product ranges

Your market research will help you to identify:

- whether your garments are likely to be in demand

- the price at which they will be sold

- how much your prospective customers would be prepared to spend on each order

To estimate your annual sales income the next step is to decide how many customers you are likely to have and how much each of them will spend.

Research current trends, plus legal and tax issues

- Sector trends for clothing manufacturers

- Legal issues for clothing manufacturers

- VAT rules for clothing manufacturers

Establish your customer profile

Depending on the nature of the garments you produce, your customer base may include:

- independent fashion clothing retailers

- specialist clothing retailers (for example sportswear, bridal wear, lingerie, work wear and so on)

- the clothing multiples, for whom you may produce some or all of their stock

- designer brands for which you provide, for example, a cut, make and trim service

- department stores and mail order/online retailers. The buyers for these businesses will be concerned that you will be able to meet their quality and delivery targets

- clothing wholesalers

- specialist wholesalers/cash and carries which cater for a specific type of trade. For example, you might produce work wear for the catering or hairdressing and beauty sectors

- procurement agencies buying garments for the public sector

- members of the public, if you decide to retail your garments as well as manufacture them

It is very important that clothing manufacturers keep up with trends and produce what consumers want, so where possible it is a good idea to work closely with your retailer customers when putting together new ranges. Retailers will also want to know how quickly you can respond to changes in fashionable styles and colours and let them have new product lines. In the past the clothing industry worked to a two-season cycle but now consumers are looking for new clothing ranges more frequently. This creates opportunities for those clothing manufacturers who can produce short runs and deliver them quickly. To do this it's important to make sure that your own suppliers - of fabric, yarn, trimmings and so on - can provide you with a similar rapid-response service.

Samples

Don't forget that buyers will want samples of your clothing ranges. Don't overlook the cost of producing these.

Special offers and discounts

Be aware that your larger customers in particular will want sizeable discounts from you in return for volume purchases and regular orders.

You might also offer early settlement discounts if customers pay their bills promptly, and retrospective rebates, to encourage customers to buy in large quantities.

Exporting

The government has a number of initiatives to help clothing manufacturers to sell to overseas markets. UK Trade & Investment is a government body that supports UK enterprises doing business abroad. Details of the help available are included in the Department for Business and Trade website. The UK Fashion & Textile Association (UKFT) export team can advise on which overseas trade shows would be most suitable to exhibit at. There is also information for first-time exporters on the Gov.uk website.

Remember, too, that the substantial fall in the value of the pound following the vote in June 2016 to leave the EU will give a significant boost to any export drive as your goods become more affordable in the overseas market.

What clothing will you produce?

What range of garments will you manufacture

There are a number of things to consider when thinking about the garment ranges you will produce:

- will your customers be male or female, or both

- will you target a particular age group such as babies, adolescents, the under-25s, retired people and so on

- will you also focus on a particular 'niche' market such as exclusive lines for the more mature woman, fashion items for teenagers, formal clothing for young professionals and so on

- will you make any of your clothing from Fairtrade cotton

- where in the market will you position your products - budget, mid-price or high

Once you've decided on your target customers, you can think about the type of garments to make and the nature of the fabrics to use. You might decide to specialize in a certain type of clothing or you might make a wide range, particularly if you are planning to establish your own brand name. Also give some thought to how many different sizes you will make each of your ranges in. Bear in mind that there is increasing demand for plus sizes in all age groups.

There are many different types of garment to choose from - some examples include:

- trousers, dresses, formal jackets, suits, skirts (for both day and evening wear)

- shirts and blouses

- T-shirts, sweatshirts, joggers, fleeces

- knitwear

- outerwear such as coats, macs and jackets

- bridal wear

- sportswear - including 'athleisure' wear

- technical clothing such as ski wear

- equestrian clothing ranges

- uniforms

- work wear, for example for the retail sector, or for hairdressing and beauty salons

- lingerie, nightwear and loungewear

- swimwear

- scarves, gloves and hats

- socks, tights and stockings

Think also about the way in which you will package and sell your ranges - for example, will you require retailers to buy your whole range in all sizes or will you be prepared to be more flexible.

It may be that you will be providing a cut, make and trim service to a major customer such as a High Street clothing chain, or to well-known designer brands. If this is the case you will work to their designs and specifications rather than designing and making up your own clothing ranges.

Production methods

There are a number of different stages involved in the manufacture of an item of clothing:

- the garment is designed by a fashion/clothing designer (you might employ an in-house designer or use the services of a freelancer)

- a pattern cutter then works on the designer's drawings and works out the shape of the different pieces of fabric that will be needed to put together the designer's creation. A standard prototype is produced (for example, in a woman's size 12)

- a pattern grader then works out the shapes of the pieces of material that will be needed to produce that design in a range of different sizes. This is often done on a computer, which then prints out a full size pattern for the fabric cutters to follow. (In some firms a computerised cutting machine does this job.)

- the individual pieces for each garment are then sewn together by sewing machinists, using a range of different types of machine to do specific jobs, for example, overlocking machines to finish off seams or specialist buttonholing machines. Sometimes each machinist does just one task, such as seaming, but in other workshops machinists work on completing the whole job, using a number of machines and different skills

- once each garment is completed it is taken over by the finishing department, to get it ready for sale. Finishing might involve steam pressing, putting the garments on hangers, protecting them with plastic bags, attaching labels and so on. The quality of the garments is carefully monitored

- finally the items are packaged, ready to be distributed to retailers and wholesalers

Although many of the processes are highly automated in some businesses, in others the work is still very labour-intensive. Where highly-priced, top quality, hand finished garments are being produced, UK clothing manufacturers can compete with overseas manufacturers - however it is difficult to compete with overseas firms which mass produce low price clothing ranges using cheap labour.

Whichever production methods you plan to use, there are a number of things to consider:

- your staff. From time-to-time the textile industry suffers from shortages of skilled and experienced designers and technologists such as pattern cutters. If you're considering setting up in a rural location, recruiting enough skilled employees may be a problem. Once you've taken on your workforce, think about how you'll keep them motivated so that your productivity remains high

- how will you make sure that you can meet delivery targets. What contingency plans will you put in place to cover unplanned stoppages such as machinist absences, machinery breakdowns, quality problems or occasions when vital raw materials haven't turned up

- how will you keep the number of 'seconds' to a minimum

- what steps will you take to make sure that your garments are of a consistently high quality

Fairtrade clothing production

Recent years have seen an increase in consumer demand for ethical products in the UK, so more and more retailers are looking to source Fairtrade labelled goods. By manufacturing clothing that carries the Fairtrade Mark you'll be able supply retailers looking to meet this increase in demand. You may well find that you also attract new customers by demonstrating that your business is ethically aware.

What is Fairtrade?

Fairtrade guarantees a fair deal for producers and farmers in the developing world by making sure they receive a fair price for their work and goods. Fairtrade products are sold slightly more expensively than similar goods to encourage self sufficiency in the developing world. All Fairtrade products are marked with the easy to recognise Fairtrade Mark.

How does it work?

The Fairtrade system works by paying producers a set minimum price for their goods, giving them a living wage. On top of this, producers also get an extra sum of money to invest in their business or community. This is called the 'social premium'.

In return, Fairtrade producers must meet certain standards. These are set by Fairtrade International, which is the global umbrella organisation for Fairtrade. Producers must be certified by FLO-CERT before they can mark their products with the international Fairtrade Mark.

Licensing

To use the Fairtrade Mark on the clothing you manufacture you'll need to be approved as a registered licensee by the Fairtrade Foundation and sign a licensing agreement. Every quarter you'll send a report to the Foundation giving details of your purchases, sales and so on. There's a fee for using the Fairtrade Mark - the amount is based on the sales you report to the Foundation.

There are strict rules about the Fairtrade cotton content that a finished item of clothing must contain before it can carry the Fairtrade Mark. You can find out more about your responsibilities under the Fairtrade licensing agreement on the Fairtrade Foundation website.

Where to get raw materials

If you decide to import Fairtrade certified cotton direct from a certified producer or farmer you'll need to be approved by Fairtrade International. You'll also have to sign an importers contract setting out your terms of trade to show that you're meeting Fairtrade standards. More information on becoming an importer is available on the Fairtrade International website.

Pricing

When you buy raw materials from a certified producer, importer or distributor you'll probably have to pay a little more than you normally would for your supplies. The slightly higher prices cover the set price and social premium paid to the farmer or producer and the cost of certification.

Although you'll pay your suppliers more for Fairtrade cotton, you'll probably be able to sell your Fairtrade marked clothing on at a higher price. People are often prepared to pay a little extra for Fairtrade goods in the knowledge that they are helping the disadvantaged producer or farmer. The Fairtrade Foundation has no control over prices in the supply chain, aside from setting the price to be paid to the producer or farmer.

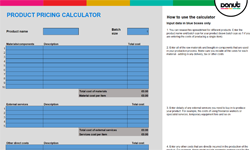

Free pricing calculator

Free pricing calculator

Setting the right price right is essential. Too high, and you'll struggle to make the sale. Too low and you're throwing away potential profit.

Make sure the price is right with our free product pricing calculator. Answer a few quick questions to work out what you should be charging.

Promoting Fairtrade goods

The Fairtrade Foundation can help you with advice and promotional materials when you launch your product. As a registered licensee you'll automatically receive a listing in the Fairtrade National Purchasing Guide. This can help bring business your way from retailers looking for a Fairtrade supplier. The Foundation also organises a Fairtrade Fortnight every year to promote the Fairtrade system. This could be a good time for you to attract new customers and to encourage existing customers to buy your Fairtrade clothing. Why not produce a sample pack of your Fairtrade products or a leaflet explaining how the Fairtrade system works and how it could benefit their business? You could distribute these to both existing and potential customers.

Where to find out more

The Fairtrade Foundation is responsible for all aspects of Fairtrade in the UK - including the registration of licensees to use the Fairtrade Mark. For more information visit the Fairtrade Foundation website.

Fairtrade International is the umbrella organisation for the National Fairtrade organisations. Fairtrade International is responsible for standard setting and FLO-CERT is responsible for certifying producers and importers. More information is available on the Fairtrade International and FLO-CERT websites.

Promoting your manufacturing business

It's very important to give some thought to how your prospective customers will know about you and your clothing ranges. This is especially important now as so many of the High Street clothing chains and supermarkets look to source their ranges more cheaply from overseas. This means thinking about how you might market your ranges on your own account. Another way might be to establish close links with the producers of more exclusive 'niche' designer branded clothes who are prepared to pay a little more for high quality and the convenience of dealing with a UK supplier.

There are a number of ways in which you can advertise your business and market your clothing ranges, such as:

- exhibiting your ranges at local, regional or national trade shows for the clothing industry

- obtaining a listing in an online directory - for example the Make it British or Still Made in Britain directories

- contacting potential customers - such as independent clothing retailers, mail order catalogues and online retailers - and showing them your product samples

- sending samples and details of your ranges to the editors of fashion magazines, in order to gain publicity for your clothing brand

- creating your own website with an online ordering facility or selling through eBay Shops

- using social media like Facebook and Twitter to promote your brand and preview new season's ranges

Ideally you will aim to get repeat business from your customers, so excellent customer service will be an important marketing tool.

Pricing policy

How will you decide on your prices?

Getting the price right is very important. It's essential to make sure that the difference between the cost price and the selling price of your garments is enough to cover all of your operating costs, including your own drawings.

It's also important to earmark some income to invest in new equipment and technology. Not only must you be able to replace machinery when it breaks down but also you might want to buy labour-saving equipment to help you to keep your unit costs down. You might also need a different range of machinery to be able to offer services like sequinning.

Your two largest items of expenditure are likely to be on:

- raw materials, such as fabric, yarn, components and trimmings

- staff costs, including outworkers

so it is very important to monitor your raw materials costs and to make sure that your workforce remains productive, that wasteful processes are reduced as far as possible and the number of 'seconds' kept to a minimum.

To monitor your performance you could regularly look at the relationship between your raw materials costs and your turnover, and your direct labour costs and your turnover.

Don't forget that if you plan to sell to both trade customers (such as retailers) and members of the public (for example by mail order or online) your trade customers will expect a trade discount from the recommended retail price.

Buy an existing clothing manufacturing business

You might decide to buy an existing clothing manufacturer rather than start your own venture from scratch. Buying a going concern can mean that the products, customers, regular sales, staff, premises and equipment are already in place.

Your market research into the sector as a whole and, if you are planning to serve local markets, the locality in particular will help you to establish whether or not the owner is selling because he or she can no longer generate enough income from the business. This may not necessarily deter you - many business people are confident that they can turn a failing business around. The important thing is to have established the current position so that the price you pay for the business is not too high.

Other matters to consider include:

- the state of the premises, sewing machines, equipment and so on. Will you have to spend money refurbishing or replacing assets

- the condition and value of any stock you are buying such as fabric, yarn, trimmings and completed garments. Check this over carefully before agreeing a price. Stock that is damaged or unfashionable will be almost worthless

But buying a business can be a hazardous, expensive process unless you have the right skills and experience on your team, including legal and financial know-how. Establish the genuine trading and financial position, so that the price you pay for the business is not too high.